In the fast-paced world of ecommerce, inventory optimization is the key to success. Ecommerce businesses need to find the right balance between meeting customer needs, cutting costs, and making as much money as possible.

Ecommerce firms can increase operational effectiveness, boost customer happiness, and generate more revenue through inventory optimization. Simply put, it helps ensure that you’re never out of stock.

To assist you in achieving the finest inventory management, we will explore the realm of inventory optimization for ecommerce businesses in this thorough tutorial.

Let’s get started.

Table of Contents

Understanding Inventory Optimization

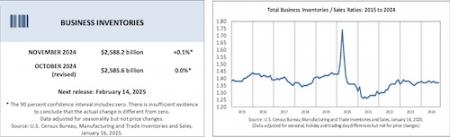

Businesses in the USA sat on $2588.2 billion worth of inventory in May 2023. This number is 1.4 times the value of sales they’re generating collectively, meaning they have more inventory than they can sell.

Image via Census.gov

Image via Census.gov

And that’s why ecommerce success depends on inventory optimization.

Let's discuss why businesses need it and its many advantages.

Why is Inventory Optimization Important, and What Does it Entail?

Inventory optimization is the proactive control of inventory levels to meet customer demand, reduce holding costs, and improve operational efficiency.

It’s about finding the right balance between having enough stock to fill orders quickly and having too much stock. After all, it costs money and takes up storage space, which is important.

Optimization of the inventory is essential for ecommerce firms. Brands can cut expenses, boost customer happiness, and gain a competitive advantage in the market by managing inventory levels well.

A good inventory management system helps businesses meet customer needs, avoid stockouts, and get rid of extra items. Reduced holding costs and increased profitability follow from this.

Benefits of Inventory Optimization for Ecommerce Brands

Here are the main advantages of inventory optimization:

- Optimum inventory levels lower holding costs by reducing storage charges and the risk of obsolescence. Inventory optimization enables companies to invest in business growth possibilities and deploy resources more effectively.

- Inventory optimization keeps customers happy by ensuring they can get what they need on-demand. It also reduces the chances of stockouts.

- Optimum inventory levels boost operational efficiency by easing order management, lowering lead times, and improving overall supply chain performance. Cost reductions, enhanced productivity, and higher profitability follow.

Additional benefits of inventory optimization:

- Higher sales and revenue

- Improved inventory turnover

- Streamlined order fulfillment

- Competitive advantage

Key Elements Affecting Inventory Optimization Solutions

Supplier relations and lead-time management are critical to ensuring order fulfillment and avoiding stockouts.

Understanding and adapting to seasonality is critical in the dynamic landscape of ecommerce for your inventory optimization.

We'll examine these crucial elements to see how they can make your ecommerce business an inventory optimization powerhouse.

Demand Prediction: The Cornerstone of Inventory Management

The basis for efficient inventory optimization is accurate demand forecasts. Online retailers can decide on their inventory levels by studying client demand trends. Demand forecasting techniques include:

- Trend analysis

- Historical data analysis

- Predictive modeling

Let's look at a very revealing example.

The world's largest online retailer, Amazon, forecasts client demand using advanced data analytics and machine learning techniques. To predict product demand, Amazon analyzes enormous amounts of data, including:

- Purchase history

- Browsing habits

- Market trends

As a result, they can maximize their inventory levels and guarantee that clients can easily access their items.

Relationship Between Lead-Time Management and Suppliers

Inventory management relies on lead time, or how long a product takes to reach the online store. Shorter lead times enable more flexible inventory management. At the same time, longer lead times might cause delayed order fulfillment and stockouts.

Working closely with suppliers lowers the chances of supply chain interruptions and helps to assure on-time delivery. Consistent communication, accurate forecasting, and open expectations are all part of inventory optimization. They help cultivate strong supplier relationships.

Recognizing the Effects of Seasonality on Inventory

For online companies, seasonality has a significant impact on inventory optimization. Demand for many things changes throughout the year because of seasons, holidays, and other events.

Case in point—the holiday season contributes a significant chunk of all sales. About 18.4% of retail sales in the USA were generated in the fourth quarter alone.

Image via Statista

Image via Statista

Successful inventory optimization and management during peak seasons and inventory reduction during slower seasons prevent stockouts and surplus inventory.

But how does seasonality work? Let's consider an example.

OneOne, an online retailer specializing in swimwear, is an excellent example of managing seasonality well. Inventory managers carefully examine previous sales data to pinpoint the seasons with the most demand, such as the summer.

They ensure they have enough inventory to fulfill client demand while avoiding too much inventory during slower months. They can do it easily by stocking up before peak season and monitoring demand.

Techniques for Efficient Inventory Management

There are many efficient inventory optimization techniques tailored for ecommerce companies. In this section, we’ll introduce you to the following strategies:

- ABC Analysis for effective categorization

- Vendor-Managed Inventory (VMI)

- Just-in-time (JIT) inventory management

- Economic order quantity (EOQ)

Let's dive into these methods to improve your inventory optimization.

Classifying and Prioritizing Inventory Using ABC Analysis

What do these categories mean? It's all simple:

- High-value products that makeup Category A may have smaller sales volumes, but they make up the majority of income.

- Products in Category B are of moderate value and substantially contribute to sales volume and revenue.

- Low-value products in Category C are those with high sales volume but little income contribution.

Inventory can be sorted into different types to help ecommerce companies manage high-value products more carefully. It will also help make sure they are available while making it easier to manage low-value items.

Vendor-Managed Inventory (VMI)

Companies use VMI as a business strategy to enhance supplier relationships and stock management. The supplier manages the customer's inventory and reports sales trends in a VMI contract.

In return, the client consents to pre-purchase a specified number of goods at a pre-decided price from the provider.

By employing this strategy, the supplier can better forecast demand and ensure sufficient inventory to meet client expectations.

Additionally, it helps the consumer plan their orders more efficiently. How? Just by providing a better understanding of product availability and cost.

Management of Inventory Just-In-Time (JIT)

Just-in-time inventory management means that products are only ordered from suppliers when they are needed for production or delivery to customers.

This helps reduce the amount of inventory, enhances cash flow, reduces waste, and lowers holding costs.

JIT may be implemented by:

- Building strong connections with suppliers

- Optimizing order procedures

- Leveraging real-time inventory tracking technologies

JIT inventory management helps firms optimize inventory levels while maintaining timely order fulfillment by carefully coordinating the arrival of goods with customer demand.

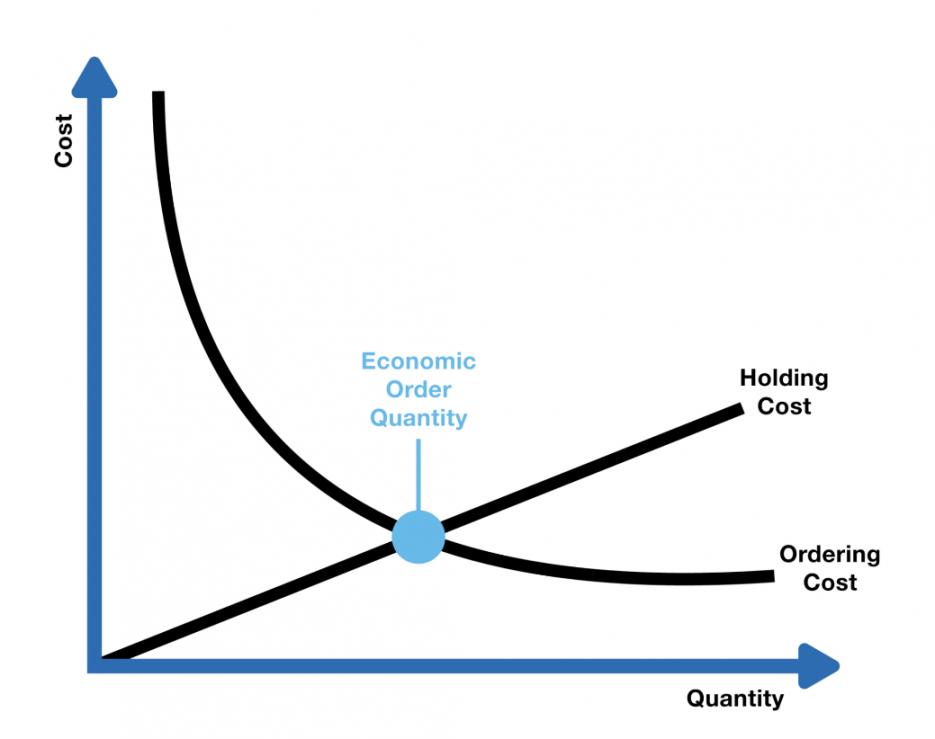

Economic Order Quantity (EOQ): Balancing Ordering and Holding Costs

The EOQ method helps ecommerce firms find the optimal order quantity, minimizing expenses for ordering and holding. It considers variables, including demand, carrying costs, and ordering costs.

Ecommerce companies may balance the expenses of maintaining excess inventory with those of placing frequent small purchases by calculating EOQ.

Image via BlueCart

It guarantees that the proper quantity of goods is ordered at the right time, saving costs and optimizing inventory levels.

Best Practices for Inventory Optimization

We've covered the best ecommerce inventory optimization practices, from safety stock levels to advanced technology usage.

Establish Safety Stock Levels

Safety stock acts as a buffer to adjust for fluctuating demand, supplier lead times, and unanticipated supply chain interruptions.

When choosing safety stock levels, ecommerce firms should take into account elements like:

- Demand fluctuation

- Supplier dependability

- Customer service level agreements

Businesses can meet consumer demand while maintaining optimal inventory levels by balancing surplus and stockout risks.

Leverage SKU (Stock Keeping Unit) Strategies That Work

Online retailers should periodically review their product lines to determine which SKUs are most important for sales and consumer demand.

The SKU assortment can be rationalized to decrease complexity, carry costs, and inventory management procedures.

Effective SKU strategies can be used for inventory optimization while boosting sales and profitability.

How exactly, you ask?

Here’s how:

- Bundling items

- Cross-selling

- Bypassing slow-moving SKUs

But this requires constant study of such things as:

- SKU performance

- Consumer preferences

- Market developments necessary for this

Balance Inventory

The last thing you want is to sell all of your stock. However, you don't want to carry so little inventory that you turn customers away and lose your target market. The right software and proper inventory management can help avoid it.

Continuous Evaluation and Monitoring

Ecommerce firms ought to set inventory performance KPIs and conduct periodic data analysis to identify improvement opportunities.

Regular assessment enables continual development, ensuring that inventory optimization tactics remain successful and responsive to changing market circumstances.

Demand Forecasting and Inventory Replenishment Strategies

Here are some strategies you can employ to forecast demand and replenish your inventory.

Utilizing Data Analytics to Predict Demand

Advanced data analysis tools, such as predictive analytics and machine learning algorithms, may assist ecommerce firms in identifying demand trends, seasonality, and client preferences.

Ecommerce companies can correctly estimate demand and alter inventory levels by evaluating enormous amounts of data, such as:

- Past sales data

- Website traffic

- Social media trends

- Consumer behavior

Strategies for Proactive Inventory Replenishment

Establishing safety stock levels to account for demand fluctuations and lead time is essential for proactive inventory replenishment.

It guarantees online retailers have enough inventory to satisfy orders during unanticipated demand surges or longer-than-expected wait periods.

You could opt for automated inventory replenishment for this. However, you need to have the right tech for it. Inventory management systems connected to demand forecasting tools can optimize inventory levels automatically by triggering replenishment orders based on specified criteria.

Using Technology for Inventory Optimization

Here’s how you can put technology to use for inventory optimization.

Automation and Software for Inventory Management

Thanks to inventory management software, businesses can make data-driven choices. It gives you real-time visibility into stock levels, sales patterns, and consumer demand.

Ecommerce companies can avoid shortages or excess stock with such decisions. They can also eliminate the human factor and improve order accuracy and automate order processing and replenishment.

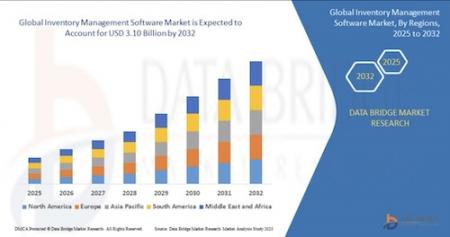

It’s no surprise then that the global market for inventory management software is expected to grow to $3.10 billion by 2032.

Image via Data Bridge Market Research

Integration with Ecommerce Platforms

Integrating inventory management systems and ecommerce platforms speeds up order processing, ensures inventory availability in online stores, and prevents overselling.

With this integration, you no longer have to manually enter data. This cuts down on common ecommerce mistakes and makes operations more efficient.

Utilizing Machine Learning and Predictive Analytics for Inventory Optimization

Machine learning and predictive analytics have entirely changed how ecommerce businesses can manage their inventories.

These tools can:

- Analyze enormous volumes of data

- Spot trends

- Produce precise demand estimates

Ecommerce firms can estimate client demand and modify inventory levels using these algorithms to reduce chances of overstocking or stockouts. They can also improve supply chain operations using the same technologies.

These technologies can give practical insights into inventory optimization by taking into account a variety of factors, including:

- Seasonality

- Market trends

- Consumer behavior

FAQ

Q1. What part does safety stock play in optimizing inventory?

A. Safety stock is a buffer against unanticipated changes in demand or supply chain interruptions. It guarantees that ecommerce firms have enough stock to avoid stockouts and keep customers happy during unanticipated events.

Inventory optimization relies on safety stock to balance supply and demand. When you have too little inventory, you risk delays in fulfilling orders and disappointing customers. On the other hand, too much inventory ties up valuable cash in excess stock. The key is maintaining just enough to meet demand without overstocking or running out.

Q2. To what extent do ecommerce platforms enjoy the integration of inventory management software?

A. Integrating inventory management software with ecommerce platforms allows real-time inventory data, order management, and stock availability. This integration ensures accurate product information and fast order fulfillment. Also, these platforms streamline processes, reduce errors, and improve customer satisfaction.

Q3. How does demand forecasting affect the optimization of inventory?

A. Accurate forecasting aids ecommerce firms in the following ways:

- Matching inventory levels with anticipated demand: Accurate predictions help businesses stock up on what customers will buy. This avoids having too much or too little.

- Decreasing surplus inventory: Excess inventory takes up space and ties up cash. Demand forecasting helps businesses avoid overordering. Instead of guessing, they plan based on real trends.

- Preventing stockouts: Running out of products leads to lost sales and unhappy customers. Demand forecasting helps businesses avoid this problem. Inventory optimization ensures products are available when customers need them.

- Enhancing overall supply chain effectiveness: Improved forecasting helps suppliers and warehouses operate more smoothly by aligning inventory with demand. Inventory optimization keeps everything moving efficiently.

Q4. Is inventory optimization achievable without compromising customer satisfaction?

A. Yes, it’s possible to preserve customer happiness while optimizing inventory. Ecommerce firms can meet consumer expectations, prevent stockouts, and enhance the shopping experience through it.

Q5. What potential drawbacks of JIT and ABC analysis as inventory management strategies?

A. Just-in-time (JIT) and ABC analysis help with inventory optimization, but they come with risks.

JIT reduces storage costs by keeping inventory low. However, any supply delay can stop production or delay orders. If a supplier runs late, businesses might run out of stock. Unexpected demand spikes can also cause problems. Without a backup inventory, businesses may struggle to fulfill orders.

ABC analysis categorizes inventory into three groups based on value so businesses can prioritize high-value products. While this approach allows for focused attention on key items, it can sometimes lead to lower-tier products being overlooked. If demand shifts unexpectedly, businesses may struggle to manage stock effectively and face shortages in overlooked categories.

Q6. How can ecommerce companies use technology to make inventory management more efficient?

A. Ecommerce companies can improve the efficiency of inventory management in multiple ways:

- Ecommerce companies can achieve accurate demand forecasting by using technology

- Automation streamlines order processing, allowing for faster fulfillment

- Making informed decisions is made easier with real-time visibility into inventory levels

- Inventory replenishment that’s optimized ensures optimal stock levels

- Technological advancements simplify inventory management and boost operational efficiency

Q7. What are some critical indicators to watch while gauging inventory performance?

A. Inventory performance is measured by:

- Stock turnover: This shows how fast you sell and replace products. A high turnover means things are selling well. A low turnover means products are collecting dust.

- Order fulfillment: Customers expect fast and accurate shipping. If orders take too long or arrive wrong, they won’t return. Tracking fulfillment speed and accuracy helps spot problems early.

- Carrying costs: Storing products isn’t free. Warehouses, insurance, and security add up. Old inventory loses value over time. High carrying costs eat into profits.

- Customer satisfaction: Happy customers mean repeat sales. If they see “out of stock” too often, they’ll shop elsewhere. Late shipments frustrate buyers.

- Backorders: This means demand is higher than supply. While this may sound good, too many backorders can hurt businesses because customers don’t like waiting.

Ecommerce companies use these indicators to assess inventory optimization success.

Q8. What is the process of inventory optimization?

A. Inventory optimization is about finding the perfect balance of stock—enough to meet demand without overstocking. You don’t want excess inventory taking up space, but you also can’t afford to run out of popular products. The process starts with tracking sales, analyzing demand, and understanding how quickly products are moving.

Conclusion

Inventory optimization is essential to the success of ecommerce companies. With it, you can cut expenses, raise customer happiness, and boost profitability.

You can also optimize inventory with accurate demand forecasts, sensible lead time management, and inventory management strategies and techniques.

And for that data analysis, technology, and strategic decision-making are all necessary.

So, go ahead and start leveraging inventory optimization so that your business can be stocked and ready for the lead generation efforts that convert.